The evolution of 3D printing technology represents one of the most fascinating journeys in modern manufacturing history. From its humble beginnings in the 1980s to today’s sophisticated machines, 3D printers have transformed from experimental devices into powerful tools that shape our world. Let me take you through this remarkable story, showing how a simple concept of layering materials has revolutionized everything from industrial production to home crafting.

Spis treści:

The Birth of 3D Printing

The story begins in 1981 when Hideo Kodama of Nagoya Municipal Industrial Research Institute invented the first modern layered approach to stereolithography. However, the real breakthrough came in 1984 when Chuck Hull invented stereolithography (SLA) and filed the first patent for this technology. Hull’s invention made it possible to create 3D models by curing photopolymers with UV lasers, layer by layer. This groundbreaking development laid the foundation for all modern 3D printing technologies we use today.

The 1990s: Commercial Growth

The 1990s marked the emergence of various 3D printing technologies. In 1992, 3D Systems created the first stereolithographic apparatus (SLA) machine that could fabricate complex parts layer by layer. Soon after, Stratasys developed Fused Deposition Modeling (FDM), which remains one of the most common 3D printing technologies today. These developments primarily served industrial prototyping needs, with machines costing hundreds of thousands of dollars. The technology remained largely inaccessible to the general public during this period.

The RepRap Revolution

A significant turning point came in 2005 with the RepRap Project, initiated by Adrian Bowyer at the University of Bath. The project’s goal was to create a low-cost 3D printer that could print most of its own components. This open-source initiative dramatically reduced the cost of 3D printing technology and sparked a wave of innovation in desktop 3D printing. By 2008, the first self-replicating printer was released, leading to an explosion in affordable 3D printing options.

Modern Era and Accessibility

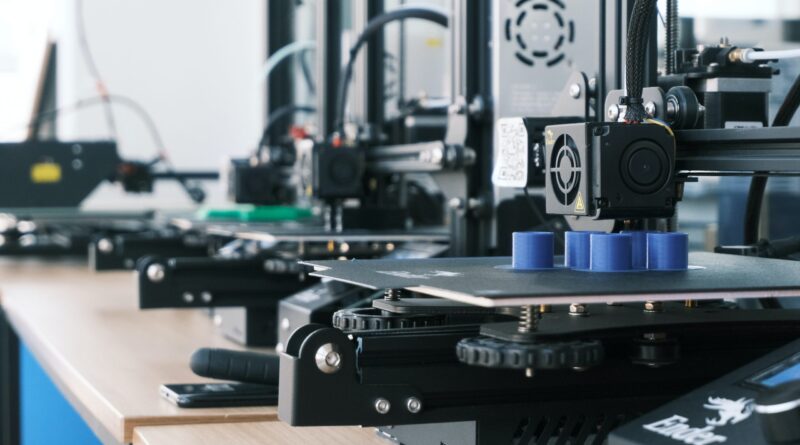

The 2010s witnessed the democratization of 3D printing technology. Companies like MakerBot and Ultimaker brought 3D printing into homes and small businesses with printers costing less than $2,000. The technology expanded beyond plastic materials to include metal, concrete, and even biological materials. Today, 3D printing serves diverse applications, from prototyping and manufacturing to medical implants and architecture. The technology continues to evolve with improvements in speed, precision, and material capabilities.

Impact and Future Prospects

3D printing has revolutionized multiple industries. In healthcare, it enables the creation of customized prosthetics and surgical models. Aerospace companies use it to produce lighter, more efficient parts. The technology has also transformed education, allowing students to bring their designs to life. Looking ahead, researchers are exploring new applications like bioprinting organs, printing entire buildings, and developing new materials that could further expand the technology’s capabilities.